In this Q&A, Corbin Independent Schools Director of Safety Thomas E. Greer explains how an intentional approach to workplace safety has improved the safety record for the district while charting a course for other schools to follow.

How many people does Corbin Independent Schools employ?

We have 400 employees serving 3000+ students and their families in our elementary and secondary school system.

What practices have you added to your program that helped improve your safety record?

The creation of our District Safety Team has been a culture changer for our district. In past years, safety was always extremely important, but the conversations and behaviors were not always intentional.

Who serves on the District Safety Team?

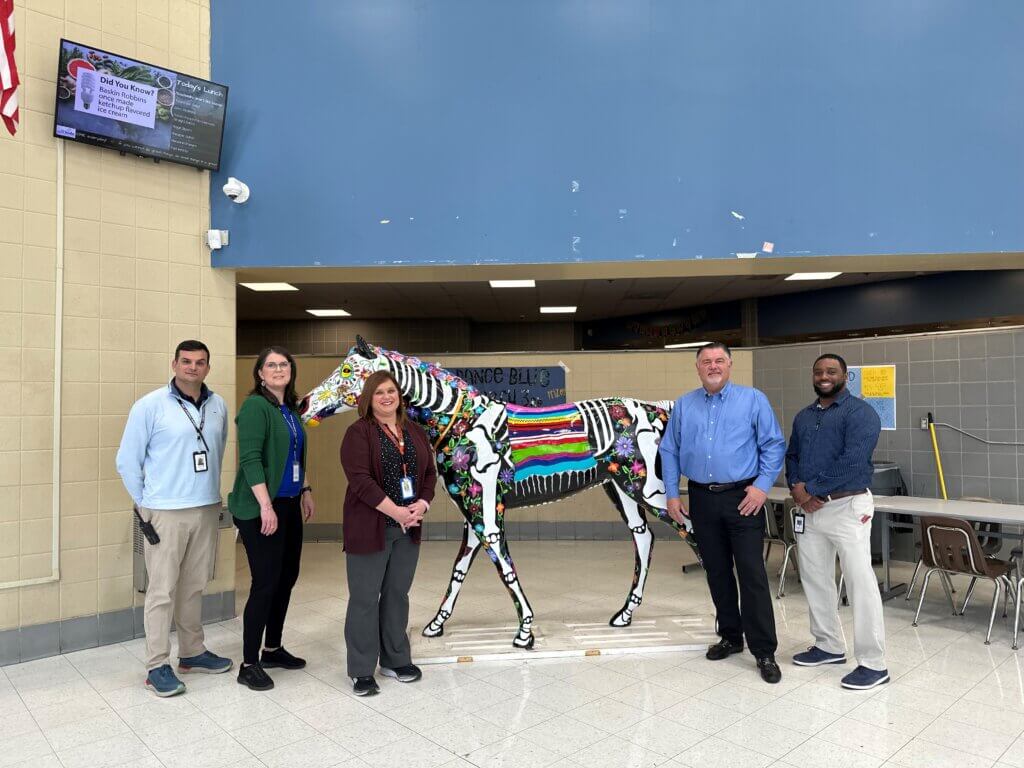

I serve alongside other district directors; school principals; supervisors from food service, transportation, maintenance, and safety; a representative from KEMI; and a representative from our insurance agency. This dedicated team meets monthly to discuss at length each building’s current level of safety and next steps.

What has resulted from the formation of the District Safety Team?

Every school in our district is part of a process each semester as we conduct safety checks that include a preconference discussion, a walk-through at several facilities, and a debriefing with the principal of each location that includes a review of claims and discussion about prevention.

Any issues identified during the walk-through that warrant correction are assigned to appropriate personnel, and progress of corrections is monitored by the District Safety Team until all issues have been appropriately addressed.

The team representatives from each school truly have a zero tolerance for exposures and pass it on to their direct reports. Their approach during the walk-through is “you find it, we’ll fix it!”

How has this focused approach helped shape safety programs for other schools?

Many schools and districts have reached out for information regarding the safety initiatives we have underway. The requests have occurred through phone calls, emails, or social media, and we appreciate the opportunity to be a resource and share practices we’ve implemented that have positively impacted our safety record.

In addition to communicating with schools, we recognize the importance of keeping all stakeholders informed about our safety measures, so we utilize our communications platform, student and parent emails, local news media, and social media to provide the community with safety program updates.

What has been KEMI’s role in helping to enhance workplace safety and reduce claims?

The district requires all faculty and staff to be certified in adult, child, and infant CPR/AED, and we rely on KEMI’s Safety & Loss Control team to provide this training. KEMI also provides first aid training for faculty and staff and, at a minimum, annual safety training for our transportation department.

I’ve seen the benefits of utilizing KEMI as a resource and that’s why I strongly encourage other schools in the surrounding area to do the same.

What notable safety recognition has your company achieved during the past several years?

For the past three years, Corbin Independent Schools earned the KEMI Destiny Award for our commitment to workplace safety. We were proud to share this honor with many community members and stakeholders who were present for the award ceremonies.